5 Popular Types Of Zipper Profiles In Resealable Bags

In the modern packaging industry, zippers, as key sealing components, are continuously meeting the diverse needs of various fields through technological innovations. From enhancing user experience to ensuring safety and practicing environmental protection, various types of zipper products are playing an increasingly important role in industries such as food, pharmaceuticals, cosmetics, and logistics, becoming a significant force driving packaging upgrades.

1.Press-to-close Zippers: Enhancing Consumer Experience and Boosting Product Sales

Press-to-close zippers are widely favored in the market due to their advantages of easy operation and excellent sealing performance. Composed of interlocking tooth-shaped components, they can tightly engage with a simple press and maintain good sealing effect even after multiple openings and closings. They effectively block air and moisture, extend the shelf life of products, and are particularly suitable for the elderly and children.

In application scenarios, apart from being commonly used in the food and beverage industry for sealing crispy snacks, frozen products, etc.They are also widely adopted in the packaging of wet wipes and facial masks in the personal care and cosmetics industry. After a well-known foreign snack brand adopted press-to-close zipper packaging for its new series of products, consumer satisfaction significantly increased, and the product repurchase rate rose by 15%, fully demonstrating its market competitiveness.

2.Child-resistant Zippers: Building a Solid Safety Barrier and Gaining Market Recognition

Child-resistant zippers are specially designed for products containing potentially hazardous substances. Their opening method has a certain degree of complexity and requires specific operational skills, which can effectively protect children while being easy for adults to operate. This feature makes them highly effective in preventing children from accidentally ingesting dangerous substances.

Currently, Child resistant zipper has become a standard configuration for the packaging of prescription and over-the-counter drugs in the pharmaceutical field, and is also widely used in the packaging of household cleaning products, reducing the risk of infants and pets coming into contact with harmful chemicals. After a pharmaceutical enterprise replaced traditional packaging with child-resistant zipper packaging, it was praised by the media and highly recognized by consumers for effectively ensuring children's safety, and its product sales have steadily increased.

3.Velcro Zippers: Solving Powder Packaging Problems and Promoting Industry Upgrades

Velcro zippers, combine the adhesive properties of Velcro with the functions of traditional zippers. They can be opened and closed extremely quickly.Their special tooth design, can fit tightly to prevent powder leakage and are not prone to static adsorption of powder during opening and closing, effectively solving the problems in powder packaging. They can precisely control the dispensing of powder, reduce waste, and prevent powder from getting damp, deteriorating, and cross-contamination.

In the food industry, they are used for packaging powdered supplements, seasonings, etc.; pharmaceutical enterprises use them to package powdered drugs to ensure accurate dosage; cosmetics companies apply them to the packaging of foundation, setting powder, and other products. A large foreign cosmetics enterprise adopted a new type of anti-powder zipper in its newly launched loose powder product, which was highly praised by beauty bloggers and consumers, triggering discussions on packaging innovation in the industry and promoting more brands to upgrade the packaging of powdered products.

4.Side-tear Zippers: Balancing Convenience and Practicality, Expanding Application Scenarios

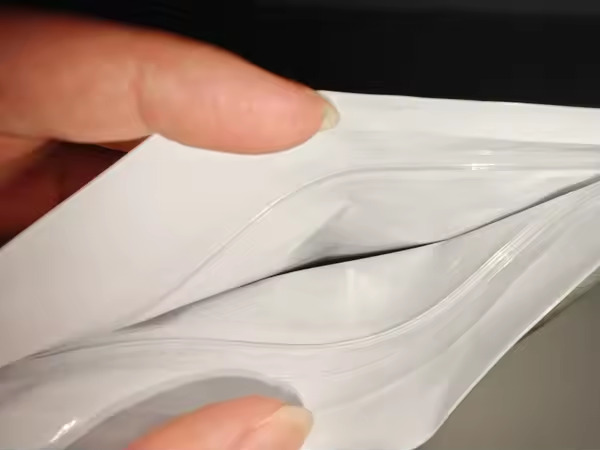

Side-tear zippers are equipped with an easy-tear opening on one side, and the zipper itself has high strength, capable of withstanding multiple openings and closings and a certain amount of pulling force. Their side-tear design is ergonomic, making opening effortless, bringing consumers a pleasant user experience, and meeting the demand for multiple uses.

Besides being used in the food industry for packaging various snacks, ready-to-eat foods, etc., they are also widely applied in the field of outdoor product packaging, facilitating outdoor enthusiasts to quickly access items.

5.Recyclable Zippers: Responding to Environmental Trends and Leading Green Packaging

Recyclable zippers are made of recyclable materials such as degradable plastics. The production process focuses on reducing energy consumption and carbon emissions, conforming to the global environmental trend, reducing pollution from packaging waste, meeting consumers' demand for green products, and helping brands enhance their environmental image.

Their applications have extended from industries such as food and beverage, personal care to the packaging of environmentally friendly series products in the clothing industry, such as recyclable clothing dust bags. Many EU countries have introduced policies to encourage the use of recyclable zippers and other environmentally friendly packaging materials.

Various types of zippers, with their unique advantages, continue to play an important role in different fields, driving the flexible packaging packaging industry towards a safer, more convenient, and environmentally friendly direction, and are expected to create value in more scenarios in the future.